Jebsen & Jessen Ingredients

Rubber Industry Solutions

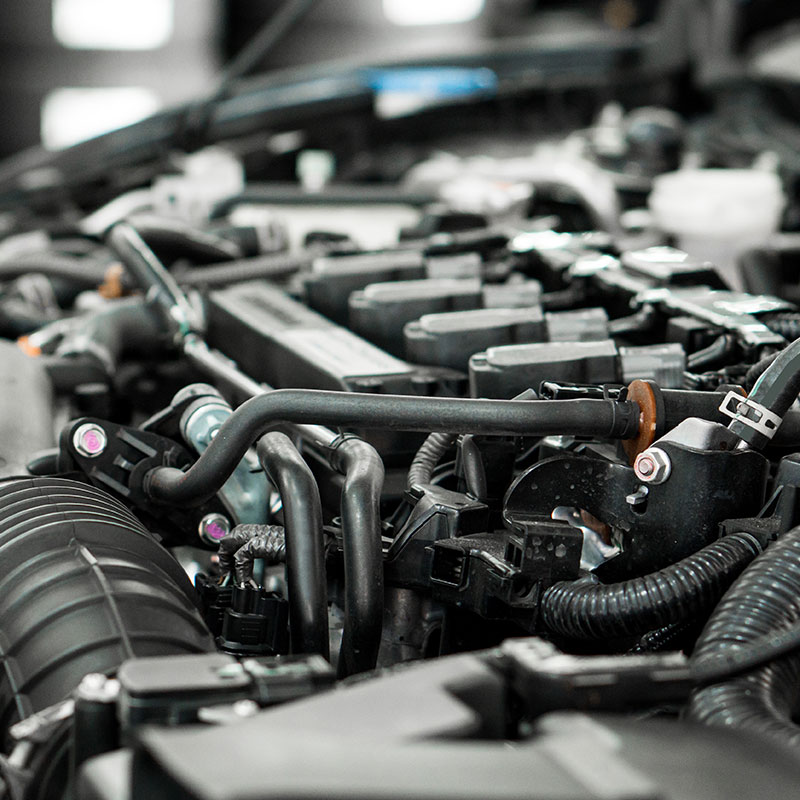

We support tyre, mechanical rubber goods, and latex industries across the region with reliable ingredients and extensive technical know-how. Find out how we can help your business.

Products

Learn more about our product solutions. We source exclusively from reliable international technology partners who are world-class innovators in the rubber sector.

industries

See which industry segments we support and how we can help businesses overcome common challenges. Our expertise and solutions are at your disposal.

Knowledge

Find out what is happening in Asia’s plastics and rubber industries. Learn more about the latest trends. See how new approaches and innovative products can help your business.

A Modern Approach to Rubber Industries

Our Jebsen & Jessen Ingredients – Rubber Business has been actively involved in the industry for decades. Our team is currently represented in eight countries across Asia and works with many of the world-leading industry players.

Our approach is and always has been to solve rubber industry challenges by working closely with our clients and partners, listening to their requirements and creating tailored solutions together with them. Every project is unique and our teams are there every step of the way, to support customers with product development, reformulations and tenders.

Take a closer look at how we support rubber industries across Asia – we’re always keen to hear from you and see how we can work together.

Our Rubber Products

Our team has a solid range of specialised products available for rubber industries. Take a look at the different product types and see how they can help your business grow.

Antifoam & Dewebbing

Show Details

Our antifoam agents help to prevent or destroy foam formations. Our dewebbing agents are used to hinder the unwanted formation of membranes between adjacent parts of a drip former once the mould has been removed from the latex (e.g. in latex glove productions).

Antioxidants

Show Details

Our team provides high-performance antioxidants that help to protect rubber products against the effects of oxygen exposure. We also provide antioxidants specifically designed for latex applications.

Antiozonants

Show Details

Our antiozonants are chemicals and/or waxes that “bleed” to the surface of a rubber article, protecting it against ozone (O3) damage.

Anti-Tacking Agents

Show Details

Anti-tacking agents create a layer between rubber products to avoid sticking together, especially in tyre applications. Due to its application in batch-off equipment, it is usually called batch-off powder or batch-off release agent.

Conductive Blacks

Show Details

Our conductive carbon blacks are often used to improve electrical conductivity and electromagnetic or thermo-conductive characteristics of rubber materials.

Coupling agents

Show Details

Our coupling agents have a wide range of benefits, such as improved abrasion resistance, higher compound modulus, lower hysteresis, improved compression set, as well as improved rolling resistance.

Crosslinking agents

Show Details

Our crosslinking agents can help to improve a variety of characteristics in rubber goods, such as thermal resistance, heat ageing, low-temperature impact, tensile strength, modulus, abrasion resistance, creep resistance, chemical resistance, stress crack resistance, heat distortion, and hot set behaviour.

Homogenisers

Show Details

Our homogenisers help to improve the homogeneity of elastomers of different polarity and viscosity. They also reduce mill bagging behaviour, extrusion rates are increased without increasing die swell, and calendering properties are improved. Our homogenisers also increases the green tack of many compounds.

Lubricants

Show Details

Our team provides a wide range of lubricants for a variety of applications. Our lubricants can help to significantly improve the flow characteristics and process behaviour of compounds during extruding, calendaring, moulding, etc. They can also reduce viscosity, promote dispersion, shorten mixing times and lower mixing temperatures and energy requirements. Also, our lubricants can improve mould removal by reducing the tackiness of the cured compound, while maintaining good compatibility with most polymers.

Peptisers

Show Details

Use of our peptisers shows reduced viscosity and nerve, translating in improved processability of polymers and the mixed compounds. Our dispersed peptisers ensure a much faster incorporation than traditional peptisers, having far superior distribution. This allows clients to overcome troublesome localised hot spots and improves batch-to-batch uniformity.

Pigments

Show Details

We provide a range of high-quality pigments, including carbon black, titanium dioxide and colour pigments.

Plasticisers

Show Details

Our plasticisers improve the flexibility and elastic behaviour of vulcanisates. They support improved hot-air resistance and increased electrical conductivity. They also facilitate the incorporation and dispersion of high filler loads.

Reinforcing Fillers

Show Details

Our team provides a wide range of high quality and consistency fillers, such as silica and carbon black, to improve the physical properties of rubber products.

Release Agents

Show Details

Our release agents provide excellent release properties, allowing for quick and easy de-moulding. They are semi-permanent and remain effective for multiple moulding cycles, increasing wall slippage and mould flow. Also, they help to reduce mould fouling and help clients to waste less time on mould cleaning. Reduced mould defects translate into direct savings.

Tackifiers

Show Details

Our high-quality tackifiers help to improve longterm building of tack in compounds and cements.

Vulcanising Agents

Show Details

Our vulcanising agent range consists of sulphur preparations and vulcanisation activators. They guarantee easy and efficient dispersion, as well as a strong activation effect on the cross-linking reactions of diene rubbers. Vulcanisation speed is enhanced and in most cases, the dynamic properties of the products are strongly improved. Furthermore, our additives can either supplement or completely replace the use of stearic acid, without running the risk of increased bloom.

Our Rubber Industry Specialisations

Our industry experts across the region have experience with many specialised rubber segments. The main focus of our team and products are tyre, MRG and latex industries.

Tyre Industries

Mechanical Rubber Goods

Latex Industries

Solving Challenges for Rubber Industries

Creating modern rubber and latex products is an advanced process with numerous challenges and potential pitfalls. Our teams are here to evaluate and advise. Take a look at common industry challenges and see how we approach these issues and help customers overcome them.

Eliminating Dusting Problems

During the production process, regular anti-tacking agents often don’t properly coat the rubber compound surface. The result is a harmful dusting problem. Our experienced team helps clients to achieve Clean Factory Concepts.

Fixing Damage to Moulds upon Release

Improper mould release can greatly impair production times, batch consistencies, and even lead to damage of the moulds themselves. Our high-quality water-based mould release agents are not only environmental-friendly, they also help reduce pre-baking times. While normally moulds have to be pre-baked with mould releasing agents, our product can be spray-applied, allowing for immediate use.

Fixing Dispersion Inconsistencies

Dispersion inconsistencies can have several negative effects on production. In the worst case, the batch inconsistencies can lead to reputation and brand issues. Our team’s high-quality homogenisers can help improve batch-to-batch consistency of compounds. Also, our internal lubricating agents improve dispersion of rubber chemicals.

Achieving Better Rolling Resistance

Improving rolling resistance in tyre applications can be a challenge to manufacturers. Our team can advise and support manufacturers with special additives to achieve better rolling resistance.

Reducing Processing Times

Processing time is a key factor in cost reduction, allowing clients to become more competitive. Our team can help significantly improve processing times with our specialised product solutions.

Latest News

Take a look at our latest news and updates. We cover new product and industry solutions, recent and upcoming events, as well as industry trends and policy changes.

Business Talk: Driving Rubber Innovation Through Partnership

At this year’s GRTE Rubber Expo in Bangkok, Steven Loh from Jebsen & Jessen Ingredients joined long-time partner Colin Clarke from Schill+Seilacher “Struktol” GmbH for a featured interview on Technobiz Business Talk.

GRTE 2025 Wrap-Up: Strong Presence, Strong Partnerships

Jebsen & Jessen Ingredients had a strong presence at GRTE 2025 in Bangkok, connecting with industry stakeholders, supporting key partners like Schill + Seilacher, and showcasing our expertise in rubber ingredients across Southeast Asia.

Join us at the 6th Global Rubber Latex & Tyre Expo (GRTE 2025)

Our rubber team will be at the upcoming GRTE 2025 – The 6th Global Latex & Tyre Expo at BITEC in Bangkok on March 12, 13 and 14. Come visit our booth at F9. See you there!